Composite Strapping: Best Practices for Safe Cargo Securing

03 November 2023

Discover best practices of composite strapping in cargo securing. Available at Westside Packaging Systems Australia, achieve load safety. Call (03) 9335 5448.

In cargo transportation, securing loads effectively is not just good practice but it is also a matter of safety, efficiency, and regulatory compliance. To date, there are numerous strapping options available in the market. But one particular type of strapping that is popular today is composite strapping.

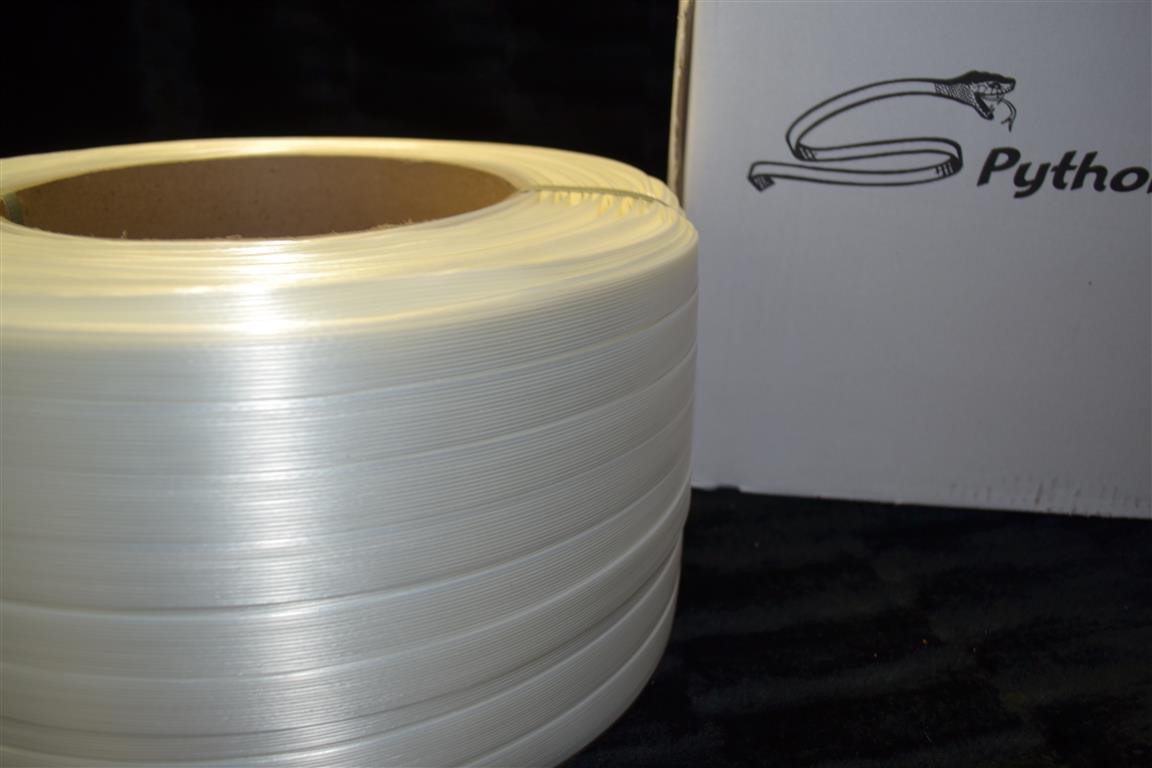

Composite strapping is a popular choice for securing various types of cargo, from heavy machinery to delicate goods. At Westside Packaging Systems Australia, we offer this type of strapping to ensure your load will be secured while being transported or stored.

Composition of Composite Strapping

Composite strapping, also known as polyester strapping or cord strapping, is a synthetic strapping material made from high-strength polyester fibres. It is a versatile and reliable option for securing loads due to its strength, flexibility, and resistance to weather and moisture.

Generally, composite strapping is known for its strength and high level of load stability and security. It also does not possess sharp edges, which reduces the risk of injuries during handling and cutting. Composite strapping is likewise resistant to moisture and weather conditions, which makes it suitable for outdoor and long-distance transportation. Other properties of composite strapping include ensured shock absorption, enhanced cost-effectiveness, and guaranteed corrosion resistance.

Composite Strapping Cargo Securing

If you will be maximising composite strapping for your items, you must utilise it optimally. Here are some practices you can carry out with composite strapping to achieve proper cargo handling.

• Select the Right Dimensions: One of the things you must do when using composite strapping is to select one with the right dimensions. You must ensure th at its width and strength will be compatible with your cargo’s weight and dimensions.

• Inspect the Strapping: Before use, you must inspect the composite strapping for any signs of wear, damage, or defects. Using damaged strapping, after all, can compromise load security. To avoid your strapping from getting damaged, you must protect it from direct sunlight during storage and transport. You must also check its condition during the transit. If any issues are detected, you must take corrective action promptly to prevent load shifting.

• Use Tensioning Tools: Another thing that you must do is invest in proper tensioning tools like tensioners and sealers to ensure that the strapping is tensioned correctly. Proper tensioning is essential for load stability.

• Apply Edge Protectors: When securing cargo with sharp edges or corners, you must use edge protectors to prevent the strapping from being cut or damaged during transit.

• Secure the Load Properly: Ensure that the strapping is applied evenly and that it forms a secure grip on the cargo. You must use appropriate techniques for different load shapes and sizes. Remember to avoid over-tensioning as it can only lead to damage to the strapping and the cargo. You must follow the tensioning guidelines provided by the strapping manufacturer.

• Use Appropriate Seals: Ultimately, you must use seals that are compatible with the composite strapping and apply them correctly to secure the strapping ends.

Cargo securing is a critical aspect of the logistics and transportation industry. Our composite strapping at Westside Packaging Systems Australia offers a reliable solution for securing various types of cargo, but it must be used correctly to ensure safe and efficient transport.

Optimized by: Netwizard SEO